Are you ready to witness a technological revolution thats already reshaping industries? Remote IoT batch jobs, once a whisper of the future, have become a powerful force, driving efficiency and innovation since yesterday.

The Internet of Things (IoT) has undeniably arrived, transforming from a futuristic vision into a tangible reality. Its influence spans across various sectors, fueling innovation and opening new avenues for efficiency. At the heart of this transformation lies the unassuming yet essential role of batch jobs, critical components in automating repetitive processes and optimizing system performance. This article delves into the realm of remote IoT batch jobs, offering practical examples, exploring effective implementation strategies, and highlighting the significant impact they have had on industries since yesterday. Our focus lies on real-world scenarios, specifically those where tasks have been initiated remotely, demonstrating the power and adaptability of this technology.

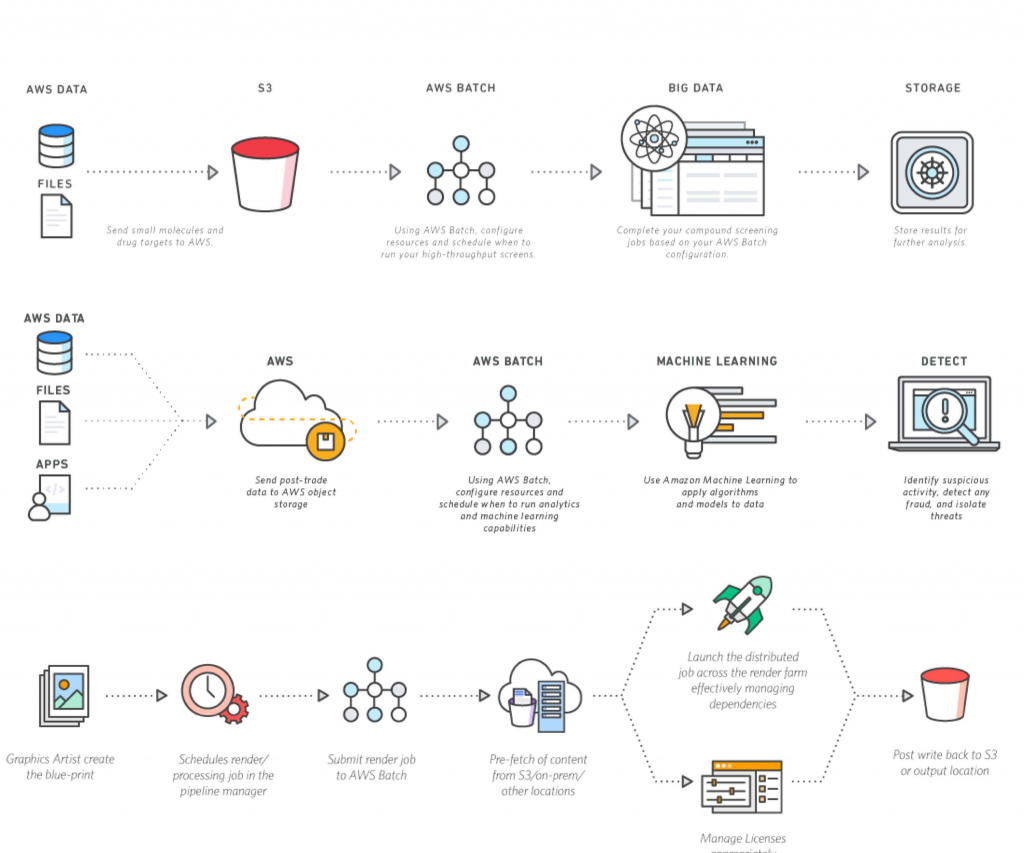

A remote IoT batch job, in its simplest form, is a predefined set of instructions or commands designed to execute automatically on your IoT devices. These jobs are the workhorses of automation, streamlining routine tasks, minimizing human error, and significantly saving valuable time. With the rise of remote work environments, these solutions have become increasingly critical, offering the tools to manage and control operations from any location.

Consider the practical application of a remote IoT batch job within a manufacturing setting. Imagine a modern factory, equipped with a network of IoT sensors meticulously monitoring the pulse of the production line. These sensors are diligently collecting data on key performance indicators, including the efficiency of machinery, energy consumption patterns, and the overall quality of the products being manufactured. This data, harvested in real-time, is then processed and analyzed through remote IoT batch jobs. For instance, a batch job could be configured to collect energy usage data from various machines every hour, calculate averages, and generate reports highlighting potential inefficiencies or anomalies. Another batch job might analyze the quality data of finished products, identifying trends and flagging potential defects. This automation allows manufacturers to swiftly identify and address issues, optimize resource allocation, and ensure consistent product quality.

The benefits are far-reaching. Data collection and analysis, device management and monitoring, these are all within the purview of the remote IoT batch job. They act as the silent guardians of the IoT ecosystem, ensuring data integrity and system stability. What was once a chore, fraught with the potential for error, has been transformed into a smooth, automated process, thanks to remote IoT batch jobs. They enable organizations to effectively manage large datasets, freeing up valuable resources and allowing for greater efficiency. Remote operations are no longer a logistical hurdle but a strategic advantage.

How do these remote IoT batch jobs actually work? They are essentially sets of automated instructions, commands that your IoT devices execute on schedule or on demand. These jobs can be triggered by events, run at specific times, or initiated remotely, providing unprecedented flexibility. The ability to execute data processing tasks in batches on IoT devices located in remote areas, this is the core of remote IoT batch processing.

The evolution in the landscape of technology is rapid, and the phrase "since yesterday" perfectly encapsulates this fast-paced environment, symbolizing the continual progress of data processing and automation. The capabilities of remote IoT batch jobs are constantly improving due to advancements in technology, making them smarter, faster, and more efficient.

The term remote IoT batch job example remote since yesterday since yesterday is rapidly gaining traction, and thats not by coincidence. This technology offers businesses the capacity to collect, analyze, and process enormous quantities of data without the need for physical presence, creating new efficiencies and reducing operational costs.

The implications are transforming industries. By leveraging remote IoT batch job capabilities, organizations can automate repetitive tasks, reduce manual intervention, and increase overall efficiency. The applications are extensive, covering areas like agriculture, healthcare, and everything in between. Consider agriculture, where sensors monitor soil conditions, weather patterns, and crop health. Remote IoT batch jobs can analyze this data, automatically adjusting irrigation schedules, applying fertilizers, and providing real-time alerts about potential problems, contributing to increased yields and reduced resource waste. In healthcare, these batch jobs can monitor patients remotely, analyze medical data, and even automate medication reminders, leading to improved patient outcomes and more efficient healthcare delivery.

These automated processes handle large datasets effortlessly, saving time and resources. This is the core of the shift: automating the routine to enable more significant progress. Remote IoT batch jobs aren't just about automating tasks, they are about empowering businesses and individuals to do more with less.

The continuous advancements in the digital landscape, coupled with the increasing need for operational efficiency, have propelled remote IoT batch jobs to the forefront of technological innovation. They play an important role in automated data processing, providing the foundation for smarter systems.

Consider the world of retail, where sensors monitor inventory levels, track customer behavior, and analyze sales data. Remote IoT batch jobs can analyze this data to optimize inventory management, personalize marketing campaigns, and improve the overall customer experience, all while reducing operational costs. Or think about logistics, where these batch jobs can track shipments, monitor vehicle performance, and optimize delivery routes. The result is reduced fuel consumption, faster delivery times, and improved customer satisfaction. These are just a few examples of how remote IoT batch jobs are transforming industries, providing efficiency gains and cost savings.

Remote IoT batch jobs have become increasingly relevant as more industries embrace remote work and automation. The integration of IoT technology with batch processing allows businesses to streamline operations, reduce costs, and improve efficiency.

The essence of remote IoT batch jobs is about ensuring the smooth running of systems and efficient resource utilization. The importance of batch jobs has not diminished; it has grown exponentially, especially in the fast-paced world of IoT.

From remote data collection and analysis to device management and monitoring, these batch jobs are versatile tools. They streamline operations, reduce human error, and save valuable time. This is the value proposition: enhancing efficiency while minimizing manual intervention.

These automated processes can handle large datasets with ease, conserving both time and financial resources. Imagine the power of these technologies in motion: from agriculture, with its sensors and data; to the medical field, where patient information is constantly updated and analyzed. The possibilities are endless, and the benefits are tangible. As we navigate the complexities of today's technological landscape, it's important to recognize the power and potential of remote IoT batch jobs.